How can we help?

Definitions related to cause analysis

The objective of this article is to provide a clear and concise definition of the vocabulary and methods used in a cause analysis process.

Cause analysis

A structured process for identifying the source of a problem or deviation from expectations. The goal is to eliminate the root cause to prevent the problem from recurring. Methods such as the 5 Whys or the Ishikawa (cause-and-effect) diagram are often used to identify the root cause(s) and implement appropriate corrective actions.

Action corrective

A measure implemented to eliminate the cause of an identified problem in order to prevent it from recurring. Corrective action aims to address the root cause with the objective of preventing the problem from recurring.

Assessment of the effectiveness of the action

Consists of verifying whether the corrective action implemented has actually eliminated the cause of the problem and prevented its recurrence. The process of evaluating the effectiveness of an action can go through several statuses: to do, in progress, effective, ineffective.

5 Whys Method

The ‘5 Whys’ method involves asking the question ‘Why?’ several times (usually five times) in order to identify the root cause of a problem. It helps to go beyond the symptoms to identify the real source of a non-conformity.

Example: Late delivery problem.

Why 1? → The parcel did not leave the warehouse on time.

Why 2? → The shipping label was missing.

Why 3? → The label printer was broken.

Why 4? → Maintenance had not been carried out.

Why 5? → There is no maintenance schedule.

Root cause: Lack of maintenance planning.

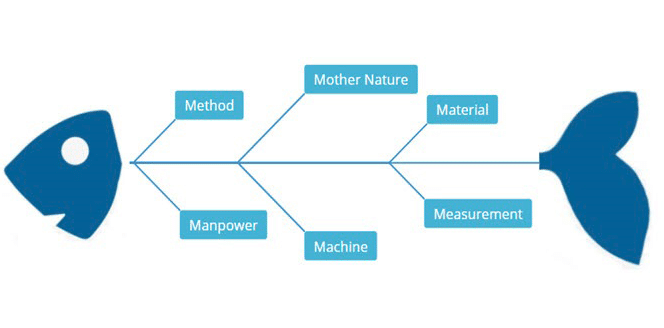

5 M methods

The ‘5M’ method is a structured approach to analysing the possible causes of a problem by classifying them into five categories: Environment, Method, Manpower, Material, and Equipment. It ensures that no factors are overlooked in the analysis.

Example for a production defect:

Environment: Workshop temperature too high

Method: Control procedure not properly applied

Labour: Lack of operator training

Material: Supplier of raw materials of varying quality

Equipment: Poorly adjusted assembly machine